Faq Sections

El Stress corrosion cracking is a type of corrosion suffered by stainless steels that generates internal cracks, which can be as well the result of a sudden breakage of the material when a force load is applied and usually generated by the high concentration of chlorides and the presence of stress on the material as such as: residual from manufacturing or generated by installation or its use, with following aspects:

– In worst cases, anchors can break under only a few tens of kilograms – less than the climber weight.

– Usually along sea sides but can be some kilometers away from the coast.

– Corrosion is not always visible. Could be invisible cracks.

– Stress corrosion cracking, which is the most virulent, could initiate cracks very rapidly after anchor installation. Within some weeks maybe, a few months for sure.

– All stainless steels, even the 316L grade, are concerned.

– The most critical factors are:

> “Moderate” relative humidity location (very dry is OK, and very humid also, in between is a problem).

> Area NOT washed by rain (even washed by the sea can be OK!!).

> Temperature is not critical, SCC can occur at 20°C, but higher temperatures are worse.

> Rock types: limestone/dolomite is generally worse than sandstone or granite (Karst is the worst case).

Only destructive testing can confirm the presence/absence of SCC on installed anchors. It is not possible to visually assess or even to casually test (like to pull on them) the effective strength of the anchors in place. Even anchors that have been installed in recent months and/or look brand new could be compromised by SCC or some forms of corrosion.stress corrosion cracking es un modo de corrosión padecido por los aceros inoxidables que genera grietas internas, pudiendo resultar en una rotura repentina del material al aplicarse una carga de fuerza, generalmente generado por la alta concentración de cloruros y la presencia de estrés en el material (residual de fabricación o generado por la instalación o el uso) con las siguientes características:

– En el peor de los casos, los anclajes pueden romperse con solo unas pocas decenas de kilogramos –menos que el peso del mismo escalador.

– Generalmente a orillas del mar, pero puede pasar incluso a algunos kilómetros de la costa.

– La corrosión no siempre es visible. Puede aparecer en forma de grietas invisibles.

– El agrietamiento por corrosión bajo tensión, que es el más virulento, podría de manera muy rápida mostrar muestras de agrietamiento después de haber llevado a cabo la instalación del anclaje. Tal vez, dentro de unas pocas semanas pero seguro dentro de algunos meses.

– En referencia a todos los aceros inoxidables, incluso también 316L.

– Los factores más críticos son:

> Lugar de humedad relativa “moderada” (lugar seco: bien / muy húmedo también, entremedio de los dos: es un problema).

> Área NO rociada por la lluvia (es posible) e incluso estando rociada por influencia marítima).

> La temperatura no es algo crítico. Sin embargo, el SCC puede ocurrir a 20 ° C , es decir, a temperaturas más altas las consecuencias son peores.

> Tipos de rocas: piedra caliza / dolomita es generalmente peor que la arenisca o el granito (el karst a evitar).

Solo las pruebas de destrucción pueden confirmar la presencia y / o ausencia de SCC en anclajes ya instalados. No es posible evaluar visualmente o incluso probar casualmente (tirar de ellos) la resistencia efectiva de los anclajes en su colocación. Incluso los anclajes que se han instalado en los últimos meses y / o parecen nuevos podrían verse perjudicados por la SCC u otras formas de corrosión.

Ecotri zinc steel anchors are designed and approved to be installed in indoor environments (indoor closed spaces), such as climbing walls, gyms, pavilions, etc.; without any potential corrosion and with an expected ambient temperature of 0 to 35ºC. Climbing walls located near industrial areas, such as swimming pools or near the sea are going to need definitely stainless steel or titanium anchors.

Moreover this type of anchor is used in the industry sector for non-permanent installations, where the material will not remain permanently in the wall.

Inox 316L anchors are designed and approved to be installed in the vast majority of outdoor environments that are not aggressive enough to create SCC. These are usually outdoors and basically in natural areas with temperatures between 70 and -30ºC. It is important to remark that 316L stainless steel is not recommended for highly corrosive environments. For these kind of environments, Fixe, following the latest updates to the CE959 Standard, offers the material that provides the highest resistance on the market: the titanium.

In some ravines, the microbiology or chemicals contained in the water can be a potential source of high corrosion. And because of that, special attention is advised in the regular reviews of the anchors installed in this kind of environments.

Show More >>

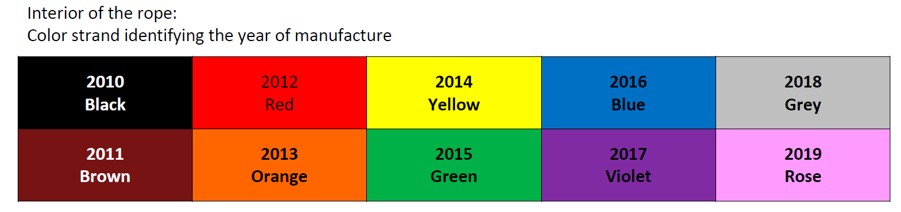

THE YEAR OF MANUFACTURE IS INDICATED ON THE THERMOADHESIVE LABEL. SEE THE USER MANUAL. IF THE ENDS HAVE BEEN CUT OR WEAR DOES NOT ALLOW THE YEAR TO BE CORRECTLY IDENTIFIED, THERE IS AN IDENTIFYING COLOR THREAD INSIDE THE ROPE. EACH COLOR HAS AN ASSIGNED YEAR OF PRODUCTION, WHICH CAN BE KNOWN BY CHECKING THIS TABLE.

Yes. Our company offers a guarantee and/or technical revision system. Our products have a three-year guarantee against manufacturing defects.

FOLLOW THE ADVICE IN THE USER MANUAL.MANUAL USER

Show More >>

A spring-loaded climbing anchor.

It is lighter and more flexible. Due to the soft aluminium and the geometry of the cams, good friction with the rock is achieved, which in turn provides more security. The first ALIEN was patented in 1986 in Colorado, USA. The current model represents the sixth generation and features 11 improvements compared to its predecessor, the ALIEN REVO. Some of them have the X-Grip texture of the cams or include the passive anchoring functionality in its three largest sizes.

In Sant Quirze de Besora, close to the Pyrenees.

Show More >>

The Perfect Descent system is a belay device used in recreational climbing, both in indoor gyms and on portable walls or climbing courses. It is installed in the place where the belayer normally positions themselves, allowing the climber to have their hands free. Once the climber is released from the wall, the system will automatically bring the climber to the ground at a constant speed, eliminating the need for a belay device. The line automatically retracts into the unit, allowing for repeated descents. It is important to note that the Perfect Descent system is not designed for lead climbing. Additionally, the system speed models can be used for speed climbing, and the 16.1 m (53 ft) speed model can be used in world record events in combination with an IFSC approved climbing wall.

The main difference between the Speed Drive and Direct Drive systems is that the former has a higher retraction speed of the lanyard. This allows climbing at high speeds while always maintaining the security that the auto belay will always be at the climber's height.

The Perfect Descent auto belay is an automatic belay device that uses a lanyard and internal braking mechanism to secure the climber during ascent and descent. The device can be used anywhere a reliable and safe climbing lifeline is needed and is attached to a solid structure. Before starting the climb, the climber secures themself to the lifeline. If the climber falls or loses control, the auto belay will bring them to a smooth and safe stop.

Show More >>